Why special generator cooling?

Usual the gas turbine generator will be cooled by circulating cooling water (water and glycol mixture) which will exchange the heat to the environmental air by fin fans. However, in the summertime the ambient temperature is such high, that the generators could not be cooled enough with the circulation water to the required operation temperature.

These borderline high operating temperatures lead to power reduced operation of the entire system and have a significant negative impact on the performance of the gas turbine (loss of power output).

In very warm regions, where a lot of energy is needed for cooling by air conditioning, these losses are very painful.

What is the benefit of installing the cooling?

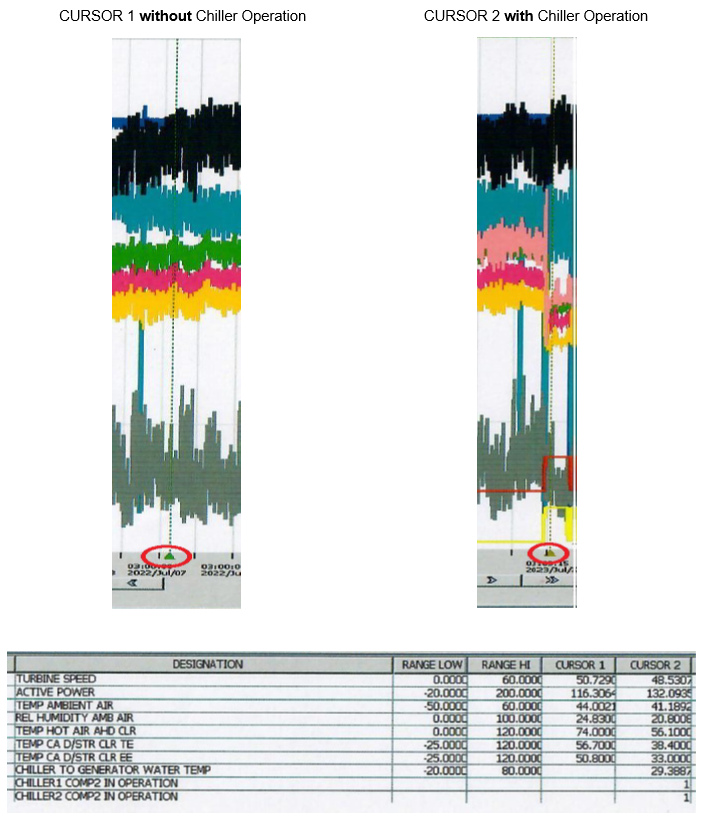

The following records was made at a SGT5 2000E gas turbine, where rotring-hische installed the generator cooling system. The records shows the operation data under similar ambiente condition when the gas turbine running with and without cooling:

In the data listed above, a constant cooling water temperature of approx. 33°C (Cursor 2) is supplied to the generator due to the operation of the chillers, instead of the 50.8°C (Cursor 1) without chiller operation.

Conclusion:

Under the given environmental conditions, in this example a gas turbine SGT5 2000E, can generate an active power output of 132 MW with the installed chiller system for the generator. In opposite to the 116 MW without chiller generator cooling. This leads to a power loss prevention of 16 MW.

What is the scope of rotring-hische?

We designed a cooling water chiller system which cools the circulating water in the generator and heats up the circulating water in the fin fan circuit.

Our Solutions include:

•Basic and detailed design and engineering

•Manufacturing

•Pre-Testing

•Packing and Delivery

•Support for Commissioning and Service

•Turnkey erection can be offered on request

The rotring-hische cooling chiller system consists of:

Chiller skid

The purpose of the chiller skid is to transfer the heat from the cooling water of the generator to the fin fan water circuit.

The chiller skid will be provided with heat exchanger (evaporator and condenser). Refrigerant compressor will be installed to pump the heat via the exchanger circuit of refrigerant to the fin fan water circuit.

Circulation pump skid

In case the chiller shall operate, the cooling water will be circulated by the pump of this skid through the chiller skid.

The purpose of this skid will be to pump the cooling water of the generator through the evaporator of the chiller skid.

The condenser water circulation to the fin fan will be performed by the existing pump skid/s.

Interconnecting piping

The generator cooling system will be delivered with material for interconnecting piping. The piping must be erected according to the related drawings. The piping will be equipped with ball valves, compensators, safety valves and all necessary measuring devices like flow switches and pressure indicators.