Designing a centrifugal separation system involves a comprehensive understanding of the principles of centrifugation, the properties of the material to be separated, and the specific requirements of the process. Here is a detailed breakdown of the design process:

Understanding the Basics of Centrifugal Separation

Centrifugal separation utilizes the principle of centripetal force to separate components of different densities, sizes, or phases. This is achieved by spinning the mixture at high speeds, causing the denser components to move outward towards the periphery of the spinning rotor and the less dense components to move towards the centre.

Design Considerations

A lot of different information are needed for the design of centrifuges separator system. For example:

Density difference; the efficiency of separation is highly dependent on the density difference between the components.

Particle size; smaller particles require higher G-forces for effective separation.

Viscosity; the viscosity affects the flow and the separation process.

Temperature Control: Important in processes where temperature affects viscosity and separation efficiency.

Pressure: In pressurized systems, maintaining appropriate pressure is crucial for optimal separation.

etc.

For the information we required for the design work, we attached the following data sheet Design Data for Centrifugal Separators. Please download the data sheet and sent us the filed data sheet with as much as possible information to our sales team.

Conclusion

Designing a centrifugal separation system requires a deep understanding of both the physical principles involved and the specific characteristics of the materials being separated. By carefully considering each aspect of the design, from the type of centrifuge to the operational parameters, an efficient and effective separation process can be achieved.

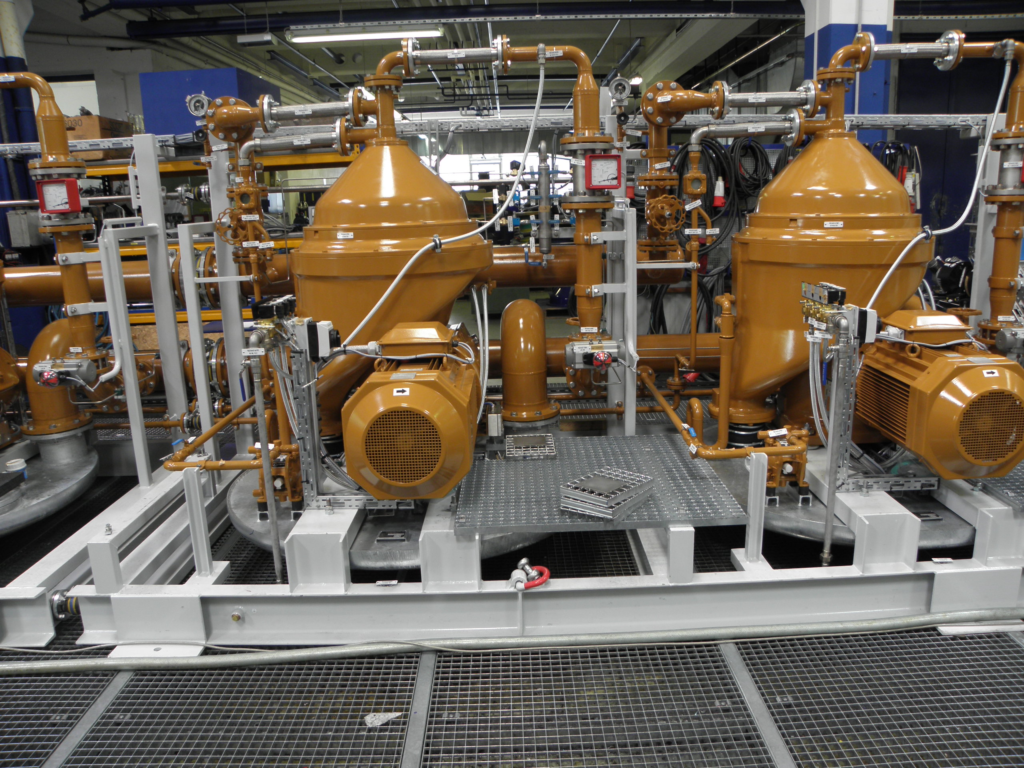

Examples of Modules